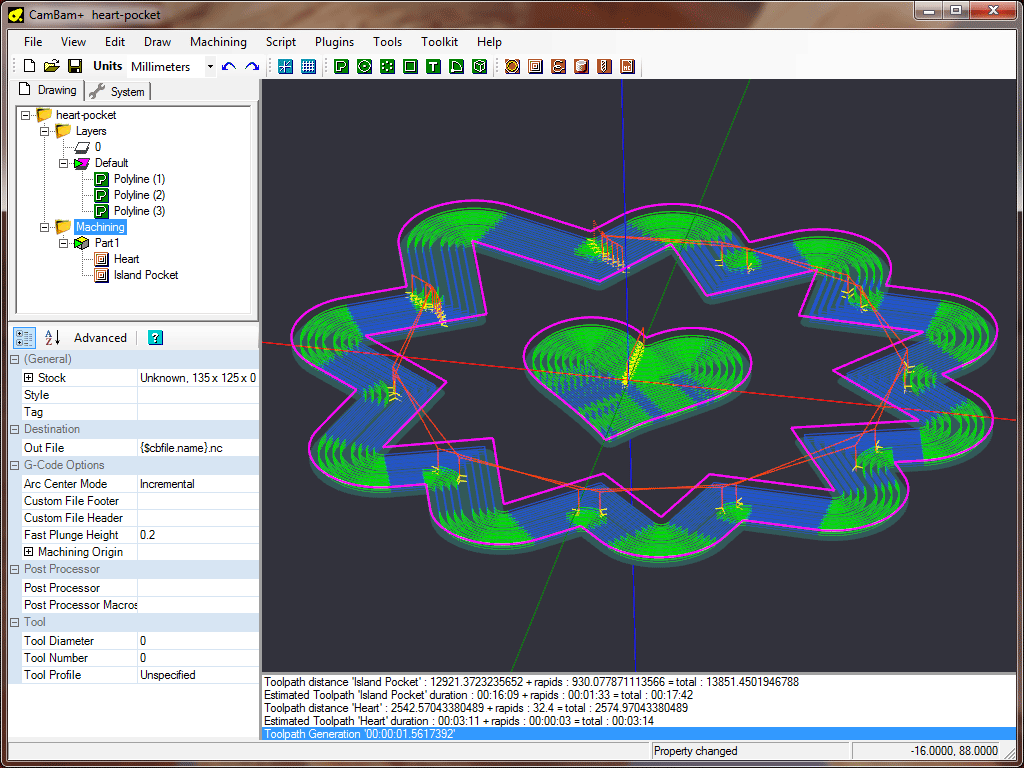

From there, you will need to enter the parameters to define the cut, which are listed in a tab format just like the Setup. To start making your cut around 2D parts, go to the “2D” drop-down menu and select the “2D Pocket” operation. With your WCS looking like the above image and your stock dimensions set, you can select ok and move on to creating toolpaths.

In this case, we already know the Z height (.72” on Z Axis) from our measurements earlier, and now you can measure your stock’s length (4” on Y Axis) and width (7” on X Axis). Under the Mode selection, I suggest using “Fixed Size Box” to fully define your stock materials. Once your project looks like the above you can go to the Stock tab and modify the dimensions of the stock material. For ease of use, many people select the bottom left corner like the above, and you want to make sure that the blue Z arrow is pointing upwards, and that X & Y are hugging your work piece.

For the most part just think of this as where the bit will be placed before you tell your machine to start cutting. The most important part of the setup process is figuring out where your Work Coordinate System (WCS) will start from. You will see a translucent box show up around your model, this represents the stock material that you will be placing in your Machine. The First focuses on making 3D models, while the second is meant to help turn a digital model into a real physical product.ĭirectly to the right of the Manufacturing tab is the Setup button, start by clicking it and the above menu should pop up. It is wise to think of each of those tabs as separate programs, with Design being for CAD (Computer Aided Design) purposes while the Manufacturing tab is CAM (Computer Aided Manufacturing). The first step in this process is (with your model visible) to go from the “ Design ” to “Manufacturing” tab in the top-left corner of the program.Īs you do so, you will see the interface change. Just like you have to set the table before you have dinner, so do you need to set up a workspace in Fusion 360 in order for your machine to know what you want it to do.

0 kommentar(er)

0 kommentar(er)